Faber

Faber Steel Dive Tank Cylinder 10.5L - 232 Bar Standard

Faber Steel Dive Tank Cylinder 10.5L - 232 Bar Standard

Couldn't load pickup availability

The Faber 232 bar, 10.5 litres (85 cubic foot), Standard, 178 mm (7 inches) diameter, Steel Cylinder with DIN/Yoke valve, cylinder boot and Nitrox ready for up to Oxygen 40% . This is the taller, standard length version of the 10.5 litres Faber cylinders.

This is by far the most popular Faber steel cylinder. It's great for shore diving, boat diving and almost any other kind of diving you can consider. Technical divers going deep and wanting longer run times often twin up two of these cylinders.

These cylinders are made by Faber, the leading European manufacturer of scuba diving tanks, with extremely high-quality steel made to international standards. Faber cylinders display a unique combination of size, weight and buoyancy.

Our tank come with updated Hydrostatic Stamp .

If you want to pick up from our shop ( Chatswood ,NSW 2067 )

Have a FREE air fill include.

And we provide high quality services such as scuba tank refills,Hydrostatic cylinder testing ,Oxygen Clean ( Include Two Wrap Decal ) and FREE tank valve inspection !!

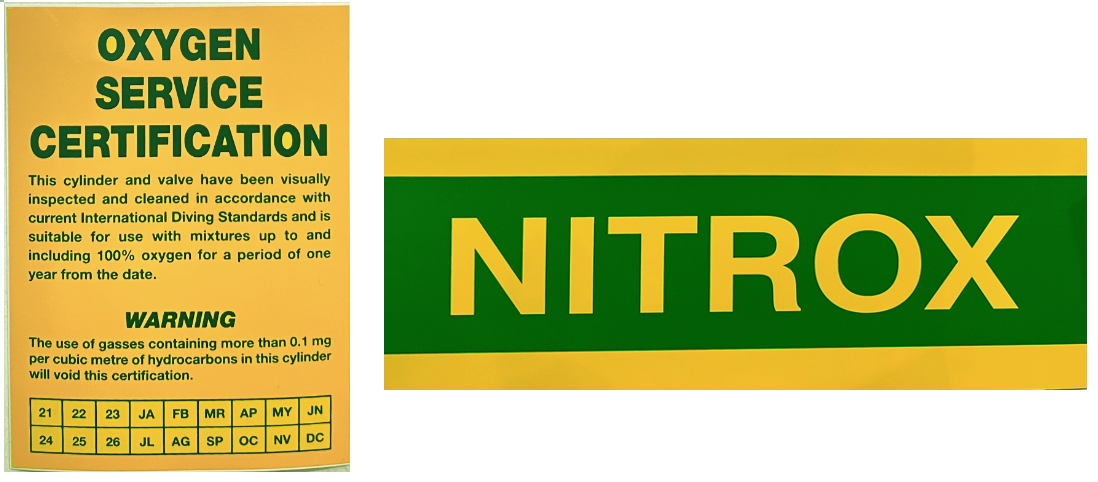

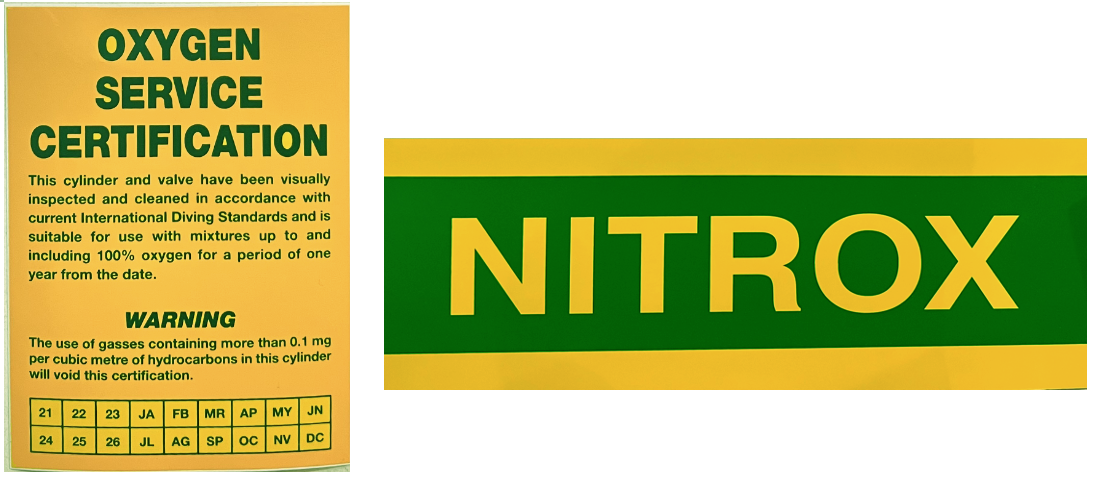

If you are planning to use the cylinder with Nitrox mixes higher than 40% oxygen, it's essential for the safety of the cylinder user and the person filling the cylinder that the tank is Oxygen cleaned. That means the valve will be oxygen cleaned and prepared with special o-rings, seats, and grease designed for exposure to pure oxygen.

Scuba tanks can be filled up to 40% Nitrox mixes without special Oxygen cleaning as long as the place filling it have pre-mixed nitrox. Otherwise, for partial pressure fills, you will need to have the tank oxygen cleaned for any mixes.

*Installation/disassemble of the tank valve must be operated by dive shop or qualified air fill station to avoid any risk of injury or death.

About Valve

This 'left' valve is considered the standard or common valve style, as the orientation is similar to commonly used valves on most dive cylinders. It's popular for use on side mount setups on the diver's left side, and for the OXYGEN cylinder on rebreathers.

This 'right' valve is considered the atypical or uncommon valve style, as the orientation is opposite to commonly used valves on most dive cylinders. It's popular for use on sidemount setups on the diver's right side, and opposite side stage bottles to keep the valves facing the same direction while keeping hand-wheels on opposite sides. It's also commonly used for the DILUENT cylinder on rebreathers.

This sidemount valve has a longer extended hand wheel for easy diver turn on and off. The recessed burst disk gives added advantage against disk damage while in wrecks or caves. Comes with O-ring, dip tube and black tank hand-wheel.

Features

- Nitrox Ready Up to 40%

- Most Widely Sold Steel Cylinder Size

- Water Capacity: 10.5 litres (85 cubic feet)

- Working Pressure: 232 bar (3365 psi)

-

Great Buoyancy Characteristics:

Buoyancy Better for Back Inflation Style BCD's (Wings)

Shed the Lead

Better Weight Distribution - Equipped with Cylinder Boot

-

Tank Construction:

Deep Drawn Chromium-Molybdenum Steel

Triple Protected Zinc Sprayed

Epoxy and Polyurethane Painted

Round Bottom Cylinder -

Cylinder Valve:

San-o-Sub DIN/Yoke Convertible Valve

Easily Switch Between Yoke and 200 bar DIN

Heavy-Duty Design

Smooth Operating Valve Mechanism

High Flow Capacity Valve

Chrome Plated Marine Brass - Made in Italy

Specification

- Fill pressure: 232 bar (3365 psi)

- Test pressure: 348 bar (5047 psi)

- Standard: BS 5045 Pt 1

- Material: 34CRMO4 Chromium-Molybdenum Alloy Steel

- Manufacturing Process: Cold deep drawing from steel plate

- External Primary Finish: Hot Zinc sprayed, layer thickness 60/70 microns

- External Final Finish: 2 part polyurethane white paint sprayed and air-dried

- Internal Finish: Chemically treated with Ferrous Phosphate

- Neck Thread: 3/4 -14 NPSM

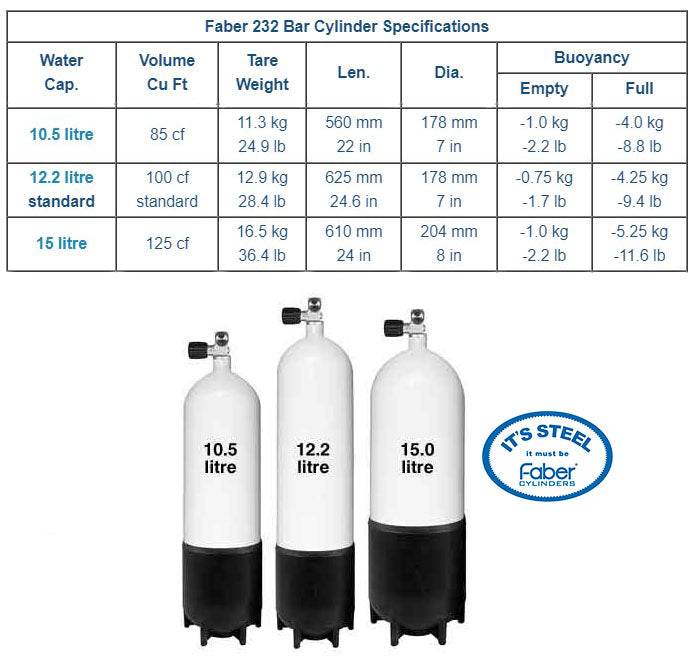

| CYLINDER SPECIFICATIONS | ||||||||

|---|---|---|---|---|---|---|---|---|

| Water Cap. | Volume Cu Ft | Tare Weight | Len. | Dia. | Buoyancy | |||

| Empty | Full | |||||||

| 10.5 litres | 85 cf standard |

11.3 kg 24.9 lb |

560 mm 22 in |

178 mm 7 in |

-1.0 kg -2.2 lb |

-4.0 kg -8.8 lb |

||

WARNING FOR PRODUCTS WHICH MAY CONTAIN CELL BUTTON OR LITHIUM BATTERY AND DANGEROUS GOODS

WARNING FOR PRODUCTS WHICH MAY CONTAIN CELL BUTTON OR LITHIUM BATTERY AND DANGEROUS GOODS

WARNING — THIS PRODUCT CONTAIN CELL BUTTON OR LITHIUM BATTERY AS DANGEROUS GOODS, PLEASE KEEP BATTERIES OUT OF REACH OF CHILDREN

- Swallowing may lead to serious injury in as little as 2 hours or death, due to chemical burns and potential perforation of the esophagus.

- If you suspect your child has swallowed or inserted a button battery immediately call the 24-hour Poisons Information Centre on 13 11 26 for fast, expert advice.

- Examine devices and make sure the battery compartment is correctly secured, e.g. that the screw or other mechanical fastener is tightened. Do not use if the compartment is not secure.

- Dispose of used button batteries immediately and safely. Flat batteries can still be dangerous.

- Tell others about the risk associated with button batteries and how to keep their children safe.

International Shipping

International Shipping

For all offshore islands and international orders, a member of staff will contact you with a delivery estimate including International freight charges. Please contact customs or your local postal service as your order may be delayed for inspection or duties/taxes may apply which are not paid for by Infinity Dive. This is applicable to all international shipping methods.

Duties and Taxes

International purchases are sold free of Australian GST. However, depending on which country the items will be dispatched to, there may be additional taxes or import duties imposed at the receivers end. Infinity Dive is not liable for these charges and it is up to the customer to liaise with the Customs regarding their delivery.

Out Of Stock Policy

Out Of Stock Policy

We will get in touch with you if the product was out of stock.

If the product was out of stock in the entire Australia, the delivery time may over 2 months.

Its depends on the ETA provided by the Brand Agent.

Cancellation Policy

Cancellation Policy

- Please note that some orders may not be able to be changed or cancelled once the order has been accepted by infinitydive.

- If you need to cancel an online order that has not yet been shipped, please contact us.

- No order shall be binding until it is accepted by InfinityDive. An individual contract for the supply of Products, on these policies, is formed on acceptance by InfinityDive of an order from the Customer.

- InfinityDive reserves the right to accept any order in whole or in part. Where we makes a part delivery of any order, such delivery shall constitute a separate contract. No order may be cancelled or varied after acceptance by InfinityDive.

In-store pickup policy

In Store Pick up orders will be available for collection in store for a period of 1 month if the product is in stock; if the order isn’t collected by this point, $10/day storage fees may apply unless a prior arrangement is made with InfinityDive.-

- There will be a payment deadline announcement to all participants, no late fee will be accepted.

- If you cancel or transfer your course due to personal reasons, you need to pay an administration fee starting from $98, which will incur within the paid fee.

- If the new course is of a higher value than the original booking, the difference must also be paid. No exceptions.

- If special circumstances or ocean conditions cause the necessary cancel on activities of the day, our students or participants who paid will get the fee convey into credit point. No direct cash return.

- If any paid fees are cancelled after 14 days due to personal reasons, the full payment will be converted into company credit points. If cancelled 7 days before departure, fee will refund by 50% deducting from the conversion payment company credit points. If the payment is made within seven days before departure, there will be no refund.

- Before payment for any activity or course, the company reserves the right to change the price, and participants must take the initiative to confirm the relevant changes.

- If an emergency medical condition manifests within 24hrs of your course start time, proof must be provided in order to transfer your course at a reduced rate depending on the case.

- If you have indicated yes to any of the questions on our dive conditional from, then one will need to be provided at the time of booking or 14 days prior to the course start date. Once you are fit to dive unconditionally, cancellation procedure will apply the above conditions. Failure to do so will result in forfeit of the course and rebooking will be at full cost.

Special Conditions

Special circumstances will deal in case-by-case manner as such medical conditions, verbal instructions, unconditional payment, etc.

Credit points

The credit points of the company after the refund can be purchased for any consumption within the company, and it will take effect forever indefinitely.

Disclaimer

Disclaimer

Please note: Due to lighting and monitors,the items colours may be slightly on the error with the pictures.

We ensure that we provide the style and the picture is the same.

Infinity Dive do not reponsible for any custom duty or import tax.

Thank you very much for your understanding!

Share